Factory best selling Socks Manufacturing Process - Men socks – Beifalai

Request A Free Quote

Product Information

✔88% Combed Cotton, 10% Polyester, 2% Spandex

✔Machine Wash

✔Ankle socks featuring lycra elastic ribbed cuff and reinforced heel and toe,Dynamic arch support helps reduce foot fatigue, Strategic cushion reduces bulk and delivers flexibility, Material wicks sweat and dries fast,Anti-odor technology helps prevent odor in the sock.

✔High Quality Soft Low Cut Ankle Socks – features organic ring spun cotton. full cushioned, durable and moisture control for all day comfort. socks’ air-permeability and moisture wicking performance keep your feet dry. premium fabric provide socks comfortable and breathable to protect your foot skin. thick padded sox for boys,teens,young,woman/women

✔Arch Support Of Running Socks – man boot socks with suitable compression in arch to protect you when you walk, jog and run and stability for a perfect fit. Elastic rib cuff can lock the hell and promise our socks Non-Slip.

✔Easy For On and Off. Good matching for all of your outdoor activities: walking,hiking.

✔Variety Colors to Choose – 6 pairs pure short rise tube socks (black,white,dark grey,light gray,red,blue,green,assorted colored). size fit us men shoes size 6-12 (small/medium/L). smooth toe seam construction eliminates bulky seams to reduce abrasion and prevent blisters. pull on closure,for everyday comfy and style, stock up on these must-have basics

✔Everyday made better: we listen to customer feedback and fine-tune every detail to ensure quality, fit, and comfort, any problem please contact us, we only want to give you a best service!

How socks are manufactured

Wet coating process: After the joints are completed, you can proceed to the next step, that is, the wet coating process. After the knitting and sewing process, the socks are washed and dried. Washing removes knitting oil and residue from the yarn and also helps to reduce any shrinkage and stabilize them. Washing is done with water only; no detergent is used.

Matching process: After the socks are washed and dried, they enter the matching zone. Here, they are pulled onto a flat metal foot mould (this is called a board foot), where they are formed into the desired shape and size. Then steam them into the final flat, neat condition.

After this is done, they can be paired. Even socks produced by the same machine, using the same yarn and settings, maybe slightly different, so the pairing process is essential to eliminate possible problems during distribution.

The last step of this process is a comprehensive quality review. When the finished product is carefully checked, it is traced back to the manufacturing process and corrected if there is an error.

Packing: After the socks have successfully passed the last quality control, they are neatly packed and ready to be shipped.

As you can see, the socks manufacturing process is carefully planned and followed. Each step follows a control review, so the quality of the final result is undisputed.

Like our latest bamboo cotton socks, they are smooth, breathable and provide maximum comfort. It is tough to find. Warm enough but never tight, they are a great addition to your winter wardrobe. Because they absorb moisture and wick away sweat, they can also prevent blisters and fungal infections.

The production of our bamboo cotton socks and pure silk stockings is based on innovative measures; all of our socks are connected by hand, which means that the toe seams are associated with a thread. This makes our socks almost seamless and even more comfortable.

Product Pictures

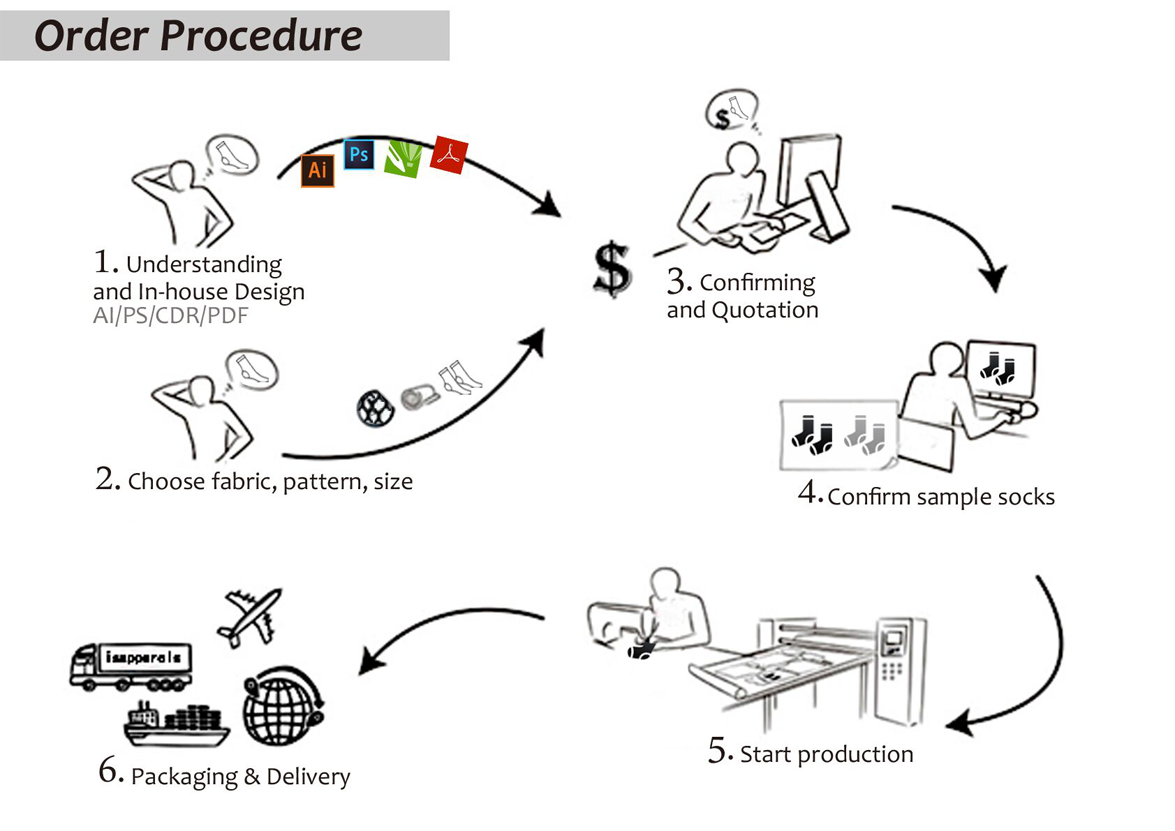

Trade Flow Chart

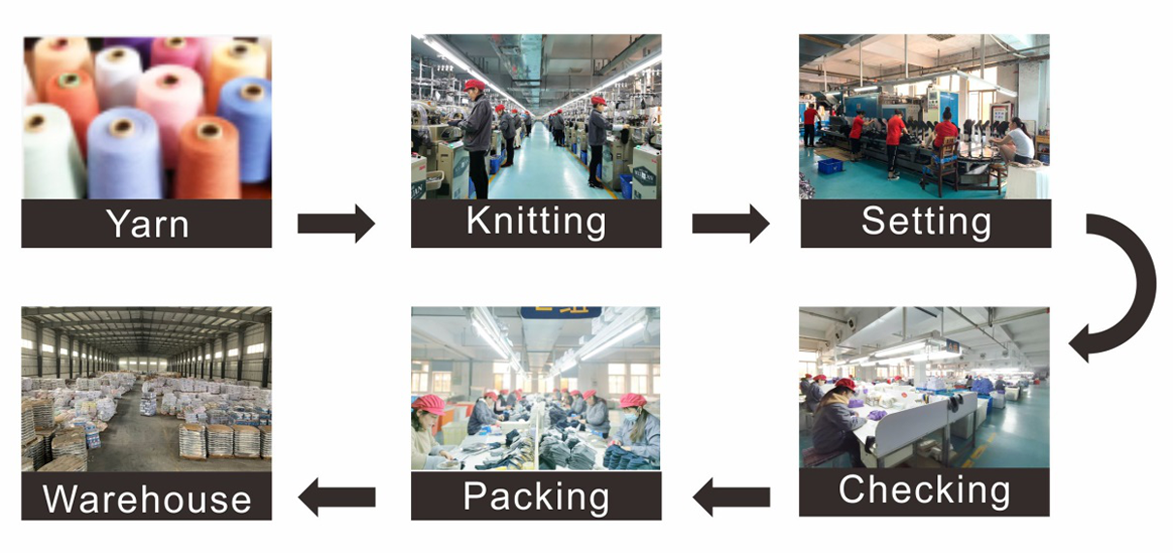

Production Flow Chart

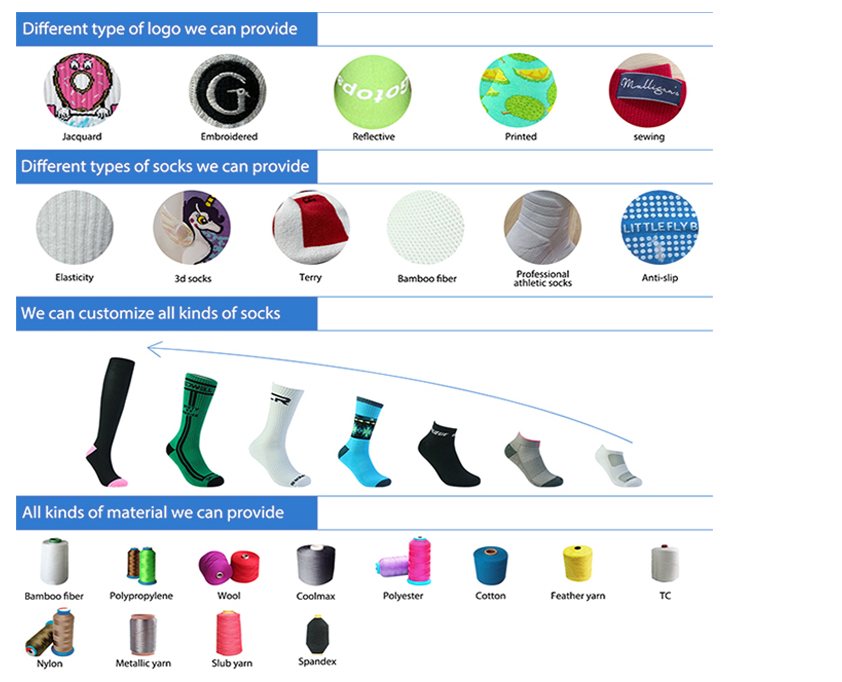

Our Services

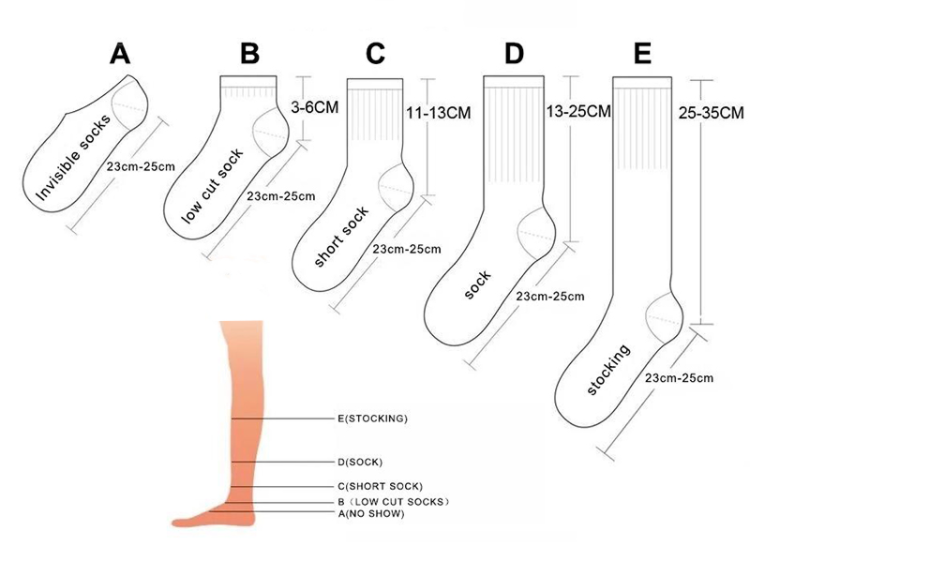

Custom Socks Size

Packing And Delivery